English

English

-

Call center (Uzb) :

+998(71) 230 95 94

- OFFICE IN TASHKENT

- In 2010, a knitting production for raw fabric with a daily capacity of 5 tons was launched.

- Launch of a dyeing factory for dyeing knitted fabrics in tops. Daily capacity: 5 tons.

- Production of cotton fabrics such as supreme (single jersey), double knit, three-thread fleece, rib, cashmere rib, and pique began.

- The dyeing factory's daily capacity reached 5 tons.

- Establishment of the company “BEK MEGA TEXTILE.”

- Launched a pigment printing division for knitted fabrics with a capacity of 2 tons per day.

- The variety of printed knitted fabrics for men's, women's, and children's clothing grew to more than 70 types.

- Launch of knitted fabric production in rolls with a capacity of 5 tons per day.

- The total production of knitted fabric increased to 10 tons per day.

- The variety of printed fabrics grew to more than 200 types, and daily capacity also increased to 5 tons.

- Began exporting products to CIS countries.

- Opened the first trading house in Kazan, Russia.

- Production and management were fully systematized.

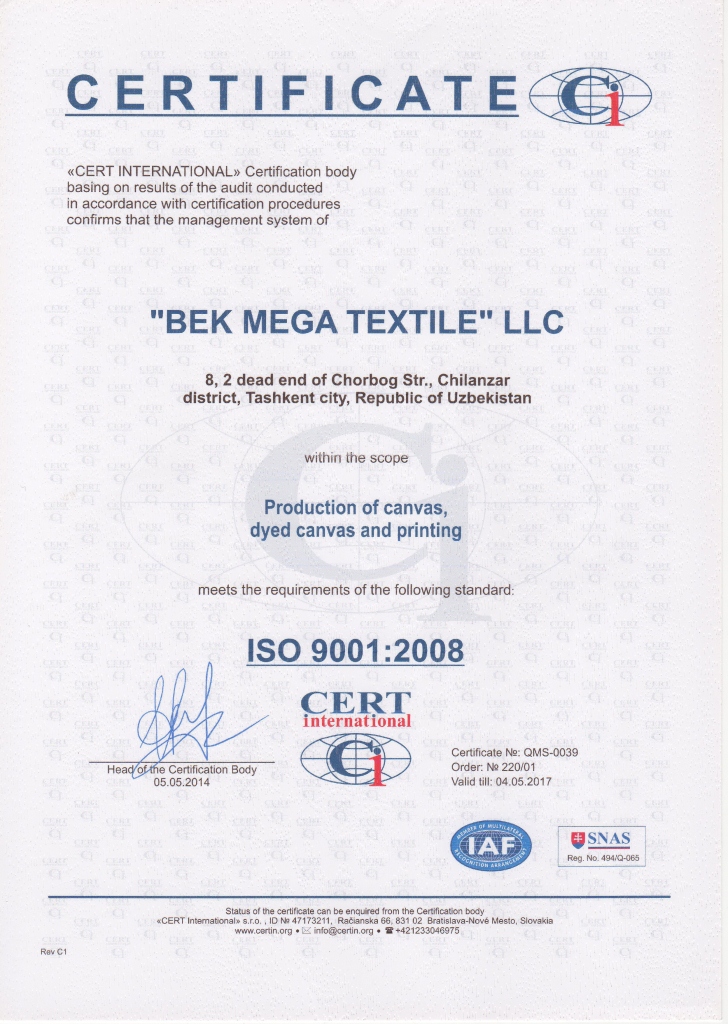

- Received ISO 9001:2008 certification from CERT INTERNATIONAL.

- Began exporting to Kyrgyzstan.

- Opened a second trading house in Ivanovo, Russia.

- Constructed an accredited laboratory.

- Modernized the physics and chemistry laboratories.

- Introduced INDUSTRIAL 4.0 system for production automation.

- Acquired a high-tech robotic assistant, which improved the quality of knitted products.

- Added new fabrics such as diagonal three-thread fleece, vaniza, selanik, ottoman, scuba, doubleface, and others to the production line.

- First entry into the American and European markets with product exports.

- Built and launched a sewing factory, creating 800 jobs.

- The daily capacity of the knitting factory reached 50,000 items, including men's, women's, and children's clothing.

- Due to the acquisition of the latest equipment from Europe, the daily production of knitted fabric increased to 20 tons.

- Variety of printed products grew to more than 500 designs.

- Despite the global pandemic, construction of a spinning factory began to ensure a full textile production cycle.

- Launched the third division in textile production—own yarn production, which enhanced quality control and ensured independence in the production of knitted fabrics.

- Produced yarn:

- Carded: Ne 20-40, 7 tons, Ring spinning method 95%. Rieter+Uster Jossi (Switzerland) + Muratec (Japan).

- Combed Compact: Ne 20-50, 8 tons, Ring spinning method 95%. Rieter+Uster Jossi (Switzerland) + Muratec (Japan).

- Staff qualification improved in all areas. Specialists underwent training abroad in collaboration with international partners.

- The company’s personnel grew to over 1,000 people.

- Neural networks were introduced to automate and manage production.

- The production capacity of fabrics in rolls was increased to 12 tons per day, while production in tops increased to 14 tons. The total production capacity reached 26 tons per day.

- Full integration of neural networks and artificial intelligence into production processes for optimization and quality improvement.

- Signed agreements to supply finished products to CIS and European countries.

Products

Our work principle is based on our motto: “HAVE IDEA, DO PASSION, BE THE BEST.” It means being unique, feeling with the heart, and always striving to be the best. This, in turn, is reflected in our results.

|

Our production process consists of four stages:

Yarn, Knitting, Dyeing, Printing, and Sewing.

Minimum annual export volume:

4.5 million finished products per year,

7,800 tons of dyed fabric per year,

2,500 tons of raw fabric,

5,000 tons of yarn per year.

|

Yarn Production

The factory produces two types of yarn:

- Carded / Carded Compact

- Combed / Combed Compact

Monthly Production Volume - 450 tons

Minimum Order - from 21 tons

Fabric Dyeing

The factory produces up to 20 tons of knitted fabric daily.

Printing on Knitted Fabric

- More than 450 different designs are used.

Production Capacity

- Dyeing and printing: up to 520 tons per month

- Minimum order: from 300 kg

The factory produces knitted garments according to international quality standards. A team of 800 specialists ensures high productivity and strict control at all stages.

Main Product Categories: Men's, women's, and children's clothing.

Production Capacity: 670,000 T-shirts per month.

Minimum Order: 8,000 pieces.

At BEK MEGA TEXTILE, we strive for sustainable development by combining respect, honesty, and innovation with environmental care. Our goal — “Responsibility” — means not only a commitment to high quality but also to environmental protection. We implement eco-friendly and “green” production processes, minimize environmental impact, and strive to use renewable resources. Every decision and action we take is aimed at preserving the planet, making our products ethical and sustainable for future generations. Our products comply with OCS ORGANIC CONTENT STANDARD and OEKO-TEX STANDARD, emphasizing our commitment to quality and health safety.

ECO-FRIENDLY FABRICS

At BEK MEGA TEXTILE, we place increasing focus on eco-friendly fabric selection. Our technical and creative teams develop collections using recycled and organic materials that meet high standards such as OCS ORGANIC CONTENT STANDARD. This allows us to produce textiles in Uzbekistan with care for the environment and a reduced carbon footprint.

SUSTAINABLE PACKAGING

We have developed an environmentally friendly packaging line. This includes FSC-certified bags and paper cartons, as well as recycled and recyclable polyethylene packaging films (certified LDPE 4). This step reinforces our commitment to OEKO-TEX STANDARD and makes us a responsible fabric and textile manufacturer in Uzbekistan.

GREEN ENERGY

BEK MEGA TEXTILE integrates solar panel energy production, generating more electricity than required for internal needs, contributing excess energy to the power grid. This reduces environmental impact and helps us maintain our status as a sustainable and environmentally responsible textile manufacturer in Uzbekistan.

PROPER WASTE MANAGEMENT

BEK MEGA TEXTILE follows a detailed regulatory system focusing on:

- Waste minimization;

- Using eco-friendly materials in packaging;

- Proper waste disposal.

These principles enable us to produce textiles with minimal environmental impact, making us a leader among fabric manufacturers in Uzbekistan.

COMPANY MISSIONS

AMBITION–DRIVEN

We seek new challenges every day and strive for excellence. We dare for more. We expect unexpected.

SUCCESS-FOCUSED

We keep developing ourselves to improve the results. We run the extra mile. We achieve our goals.

TALENT–BASED

We enable talents to grow. We appreciate the best in people. We treat others the way we want to be treated.

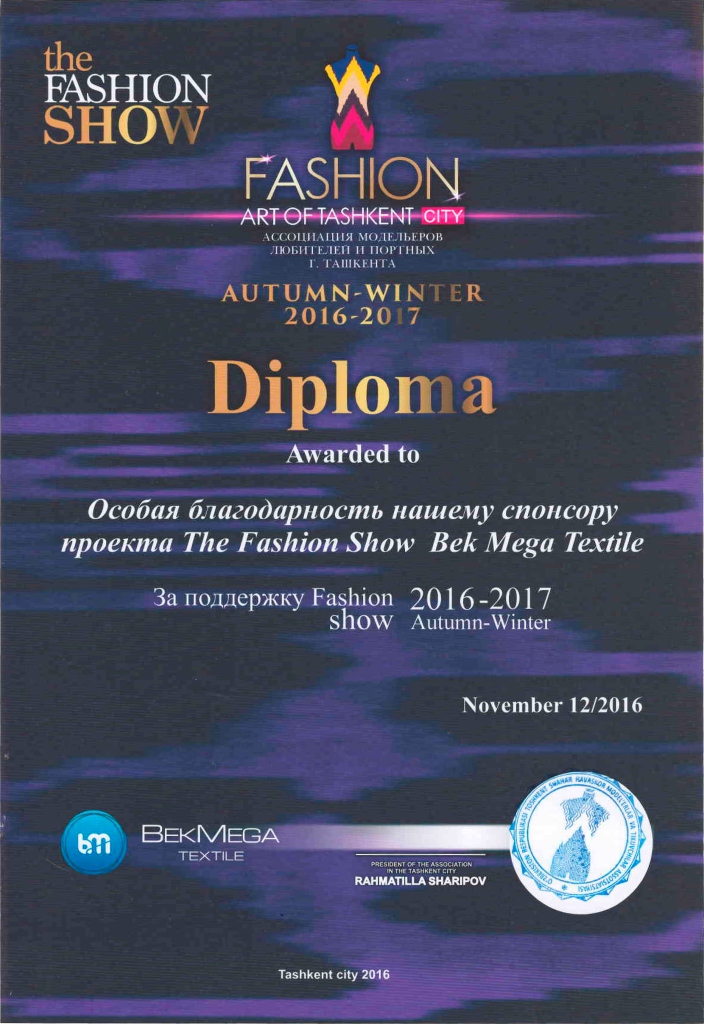

AWARDS

CLIENTS